Star Garment Innovation Center

Katunayake, Sri Lanka • 2018

A pioneering passive house retrofit in Sri Lanka creates an economic catalyst and model for sustainable development.

The Star Innovation Center is a product development facility located outside of Colombo in Katunayake, Sri Lanka. Planned as a global model for the entire garment industry, the project sets a new high bar for sustainability, energy efficiency and worker comfort.

By choosing to renovate an obsolete building to Passive House standards, the project dramatically reduces the waste, carbon emissions and fossil fuels typically required for demolition and a new build, and promotes the client’s commitment to maintain high standards in social, environmental, ethical and safety compliance within the global fashion industry.

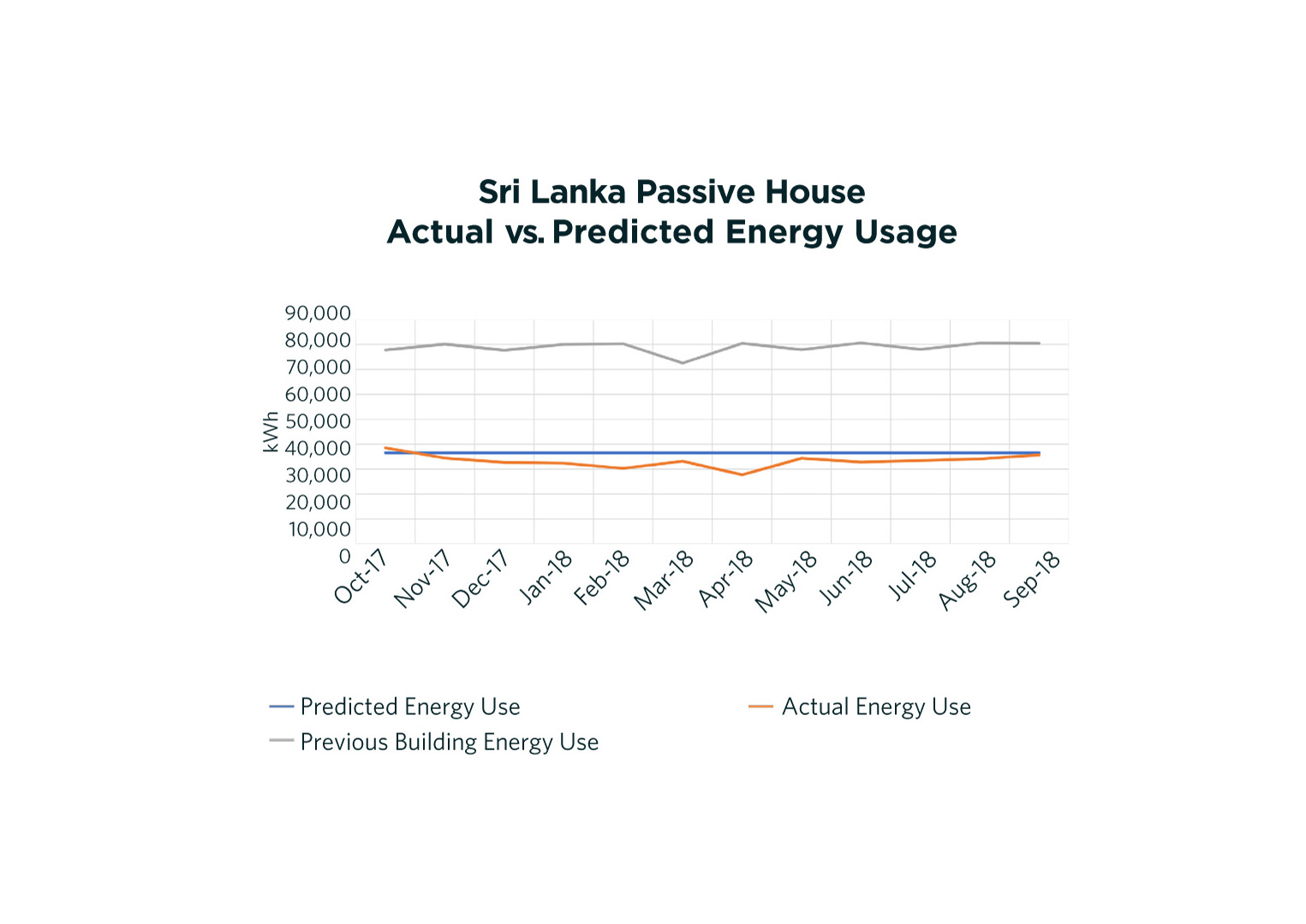

The project is the first certified Passive House project in South Asia, and one of only two certified Passive House factory buildings in the world. Annual energy consumption has been cut by over 70% compared to a conventional “efficient” modern industrial building.

The project is a pioneer in applying Passive House technology to a tropical monsoon climate, which features steady warm temperatures year round but extremely high relative humidity.

Careful design and engineering of the building systems and enclosure ensures that workers enjoy year-round comfort in a workspace that provides abundant natural light, low humidity, filtered fresh air, and maintains temperatures near a constant 24°C (77°F).

Thorough testing of the airtightness and remote monitoring of the ongoing energy usage have provided quantitative verification of the building performance, confirming projected operational cost savings for the client and vastly upgraded workplace environmental standards for the employees.

From the outset our agenda was to assemble an integrated project team including local architects, engineers, fabricators and builders to encourage technology transfer and demonstrate the feasibility of high-performance building in the region.

By promoting the project and inspiring the local building industry there is a clear path to both reducing carbon emissions and putting an end to worker “sweatshop” conditions.

Click to see video of the project being presented at Passive House Accelerator

DESIGN TEAM

Jordan Parnass

Marijke Huelsmann

Kevin Hennessey

Philip Weller

Yereem Park

CONTRACTORS

Tritech Engineering

Civicon Engineering

Alufab PLC

CONSULTANTS

Lead Architect & Interior Design -Vinod Jayasinghe Associates (Pvt) Ltd (Sri Lanka)

PH & Energy Consultants - Steven Winter Associates

Mechanical Engineering -Chandana Dalugoda Consultants

Structural Engineering -Ajith Vandebona PE

Quantity Surveying - PrasadJasinghe, VFORM Consultants

MEP Engineering - Kosala Kamburadeniya PE

Certification - DragosArnautu, Passive House Institute

PHOTOGRAPHER

Ganidu Balasuriya

Circular

SUPPLIERS

Gutman - Windows & Doors